|

26/10/12 |

|

Business Name |

|

Motors |

|

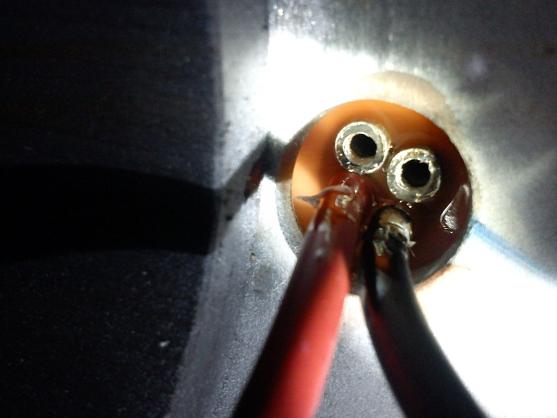

I inserted 2 stainless 6mm tubes through the shaft of the aft motor and filled the whole thing with glass fibre, leaving the pipe just flush with the end of the shaft on the inside.† The pipes stick out of the top but forgot to take a pic.† I will later.† The idea here is that I can pump oil down one tube and it will vent through the other.† This means I do not have to drill into the motor casing. Initially, I tried an epoxy potting compund but it was too viscous and would not flow into the motor shaft past the pipes and the wires.† Glass fibre worked ok.† It only needs to fill the cavity and isnít a proper pressure seal as there should be no pressure differential. I had a real game getting the motor back together as the wires have to be just the right length to clear the commutator.† At first they were too long and rubbed.† Once I had cut them to the correct length, they were really awkward to get back on.† But, bottom picture is it running ok eventually. |

|

Submersible Build Log |